What is Vacuum Pump & How Does it Works?

A Vacuum Pump is a type of industrial pump that removes gas molecules or air particles from a restricted area to create a pressure difference and a partial vacuum. Depending on the application and pressure requirements, vacuum pumps are made using a number of technologies. Sizing a vacuum pump system to the correct settings is critical for maximum efficiency. Mechanical machinery can be powered or assisted by a vacuum. A vacuum is created in hybrid and diesel automobiles by a pump positioned on the engine (usually on the camshaft). Instead, in petrol engines, a vacuum is formed as a result of the engine's operation and the flow restriction imposed by the throttle plate, but an electrically powered vacuum pump can reinforce it to increase braking assistance or reduce fuel consumption.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteVacuum pumps Subcategories

Top Companies in Vacuum pumps

+11 Companies in Vacuum pumps

Top Devices in Vacuum pumps

Related RFQs

Dry Vacuum Pumps

LNQ-24011129

Oil-sealed vacuum pumps category

LNQ-22121188

Oil-sealed vacuum pump

LNQ-22111612

Dry Claw Vacuum Pump

LNQ-22111367

LIQUID RING VACUUM PUMPS

LNQ-22101459

DRY VACUUM PUMPS

LNQ-22071511

Dry Claw Vacuum Pump

LNQ-22071432

Oil-sealed vacuum pump

LNQ-22041092

Top Vacuum pumps Experts

What are Vacuum Pumps?

A vacuum pump, which is a type of industrial pump, is a device that removes gas molecules or air particles from a confined space to create a pressure differential and a partial vacuum. Based on the application and pressure requirements, vacuum pumps are developed in a number of technologies. Sizing a vacuum pump system to the proper settings is critical for achieving maximum efficiency.

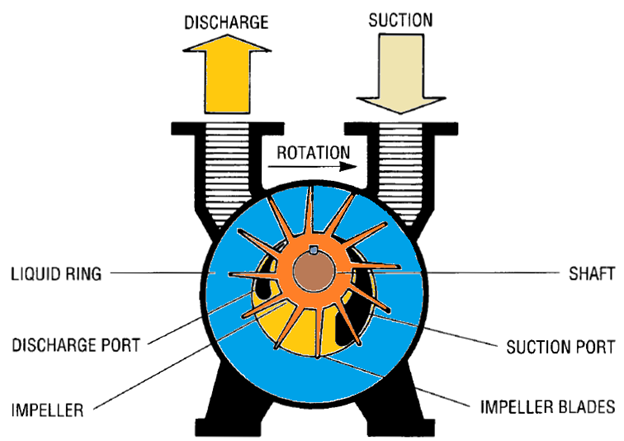

Vacuum Pump Working Principle

A vacuum is a space that is devoid of substance and has a gaseous pressure that is lower than atmospheric pressure. The main objective of a vacuum pump is to modify the pressure in a contained region in order to generate a full or partial vacuum via mechanical or chemical means. As gas molecules travel from high to low to cover the full area of that volume, pressure will constantly strive to equalize across linked regions. If a new low-pressure region is provided, gas will flow naturally from the high-pressure area to the new low-pressure area until the pressures are equal. This vacuum is formed by pushing molecules rather than "sucking" gases. By switching between high and low-pressure states, vacuum pumps basically transport gas molecules from one area to the next, creating a vacuum.

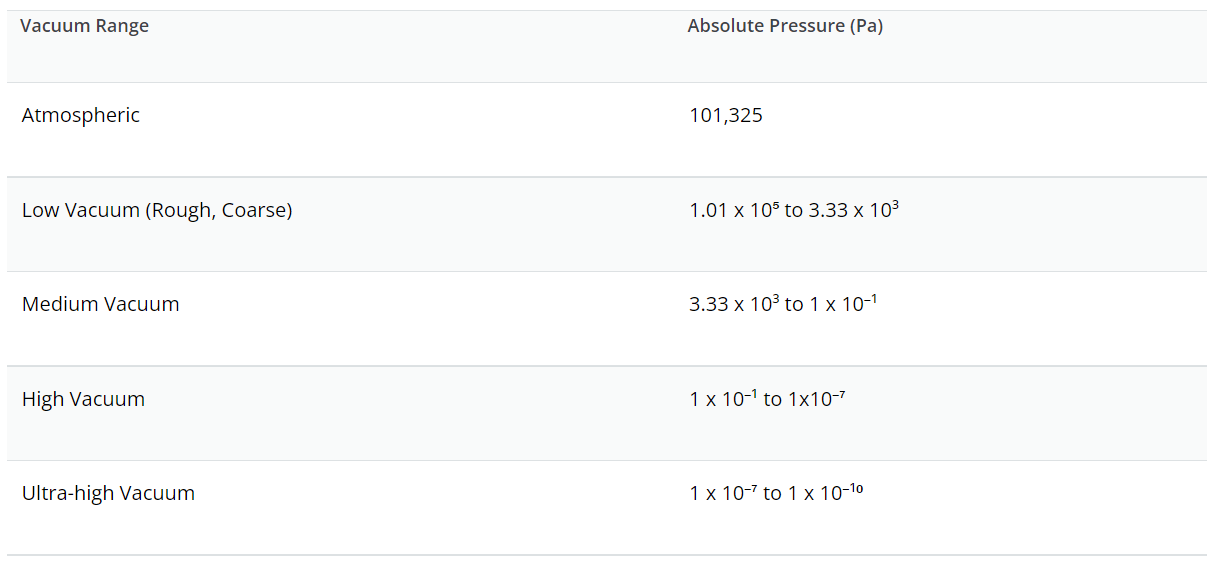

Vacuum Ranges

Vacuum ranges or regimes are classifications of vacuum quality based on the measurement of the system's absolute pressure. The absolute pressure shows the quantity of residual matter in the system, which is largely made up of gas molecules like nitrogen, oxygen, and water vapor, as well as trace gases like neon, helium, and hydrogen.

Vacuum ranges necessitate a variety of pumping strategies. Positive displacement vacuum pumps can reach low and medium vacuum levels. These are appropriate for the majority of industrial systems. Both momentum transfer and entrapment pumps may reach high, and ultra-high vacuum ranges for particular applications such as surface analytic methods, microscopy, and nanolithography.

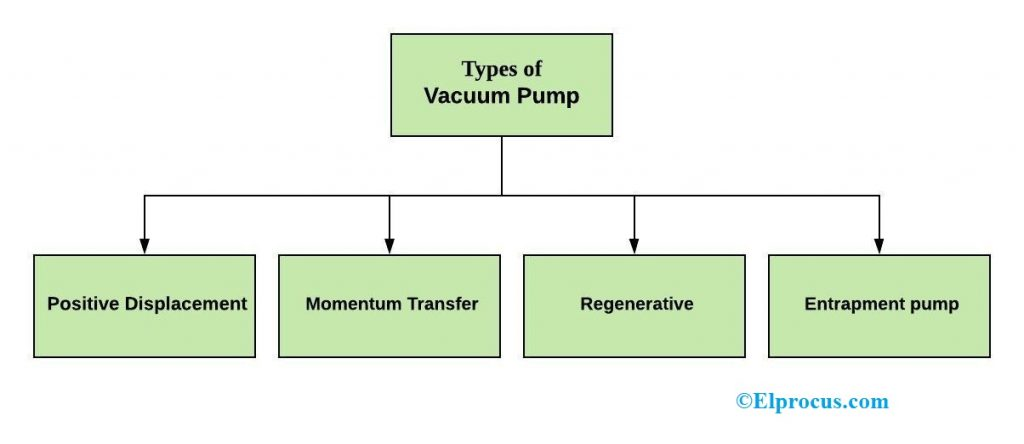

Types of Vacuum Pumps

Depending on whether the gas is exposed to oil or water during the pumping operation, the various pump technologies are classified as wet or dry type pumps. Oil or water is used for lubricating and/or sealing in wet pump designs, and this fluid can pollute the swept (pumped) gas. The pumping mechanism is separated from the swept gas by tight clearances between the rotating and static sections of the pump, dry polymer (PTFE) seals, or a diaphragm in dry pumps.

Although oil or grease may be used in the pump gears and bearings of dry pumps, they are sealed from the swept gas. When compared to wet pumps, dry pumps lessen the danger of system contamination and oil disposal. Simply changing the pump from a wet to a dry type does not change a vacuum system from wet to dry. The wet pump can pollute the chamber and pipes, which must be completely cleaned or replaced, otherwise the gas will be contaminated during future operations.

To identify their capabilities, vacuum pumps are also categorized by the pressure range they can reach. These are the classifications:

- Pumps that handle rough and low vacuum pressure ranges as primary (backing) pumps.

- Booster pumps are used to manage low and medium pressures.

- High, very high, and secondary (high vacuum) pumps handle ultra-high vacuum pressures.

Applications of Vacuum Pumps

Simply explained, vacuum pumps are mechanical devices that allow air and gas molecules to be removed from a sealed compartment to create an air- and/or gas-free environment. Their primary function is to clean and seal. Depending on the medium being pushed through them, vacuum pumps are available in wet or dry versions.

A vacuum can be used to either power or aid mechanical equipment. A vacuum is created by a pump mounted on the engine (typically on the camshaft) in hybrid and diesel automobiles. Instead, in petrol engines, a vacuum is normally formed as a result of the engine's operation and the flow restriction established by the throttle plate, but it can also be augmented by an electrically powered vacuum pump to increase braking assistance or reduce fuel consumption. This vacuum can then be utilized to power the hydraulic brakes' vacuum servo booster, the ventilation system's motors that move dampers, the cruise control servomechanism's throttle driver, and the door locks and trunk releases.

The vacuum source in an airplane is frequently utilized to power gyroscopes in different flying instruments. The instrument panel is purposefully built with certain instruments powered by electricity and others powered by the vacuum source to avoid complete loss of instrumentation in the case of an electrical failure.

Depending on the application, some vacuum pumps are powered and operated by different methods. They can be electrically driven (using electric current) or pneumatically driven (using air pressure).

You can find various Pump Suppliers and Companies in Linquip that can completely cover your requirements. You are also encouraged to visit the List of Vacuum Pump Distributors in Linquip.

Advantages and Disadvantages of Vacuum Pumps

Advantages

The following are some of the benefits of vacuum pumps.

- These pumps are used to suction and transport waste from a mining camp.

- These include spill prevention as well as odor control capabilities, allowing for convenient and safe transport of bio-solids products.

- The primary goal of these pumps is to securely transport hazardous chemicals and prevent deadly waste from entering the environment.

- They remove waste quickly and from clogged drains, which saves time and allows the operation to be completed sooner.

- These are commonly found in power jets, tipping tanks, and rear doors and are suitable for a wide range of applications.

Disadvantages

The following are some of the vacuum pump's drawbacks.

- Fluid slugs may cause damage to these pumps.

- The fluid in the pump and the process gas should be well-suited to avoid pollution.

- The vapor of the fluid within the pump might restrict the pump's suction pressure.

- At the working temperature, the attainable vacuum may be restricted due to the sealant fluid vapor pressure.

FAQs about Vacuum Pumps

- Can a vacuum pump run continuously?

The vacuum will be switched on and off by a vacuum solenoid valve, and the pump will run constantly. The venturi will only operate when it is needed (during the lift phase of the cycle), and will be controlled by a compressed air solenoid valve.

- How long should you run a vacuum pump?

Fewer vapors will condense in pump oil if you operate the pump for 20-30 minutes with the intake shut before connecting to your vacuum application.

- How often should you change vacuum pump oil?

When the oil seen via the sight glass becomes tainted, it becomes brown and foams. It is imperative to replace it with a fresh one after a lengthy time of service. Even if you don't have any of the aforementioned symptoms, it's a good idea to change the oil every 100 hours of vacuum pump operation.

- What causes vacuum pump failure?

Broken belts, electrical difficulties inside the device, or faulty vacuum hoses are the most typical causes of vacuum pump failure. If the engine is running, the pump is continually running, and wear and tear will eventually lead it to fail. You'll notice a drop in braking performance if this happens.